Stitches are the foundation of every textile or metal project. Whether in fashion, home sewing, or industrial manufacturing, the choice of the right nahttypen (stitch types) determines not only the appearance but also the durability and strength of the final product. A solid understanding of the different types of stitches helps avoid mistakes and ensures the best results.

Why the Right Stitch Matters

Choosing the correct nahttypen is not just a design decision. It directly impacts:

-

Durability: Different stitches withstand different levels of stress.

-

Functionality: Some stitches stretch, while others remain rigid.

-

Aesthetics: Visible or hidden stitches change the look of the material.

-

Efficiency: The right stitch can save time and reduce material waste.

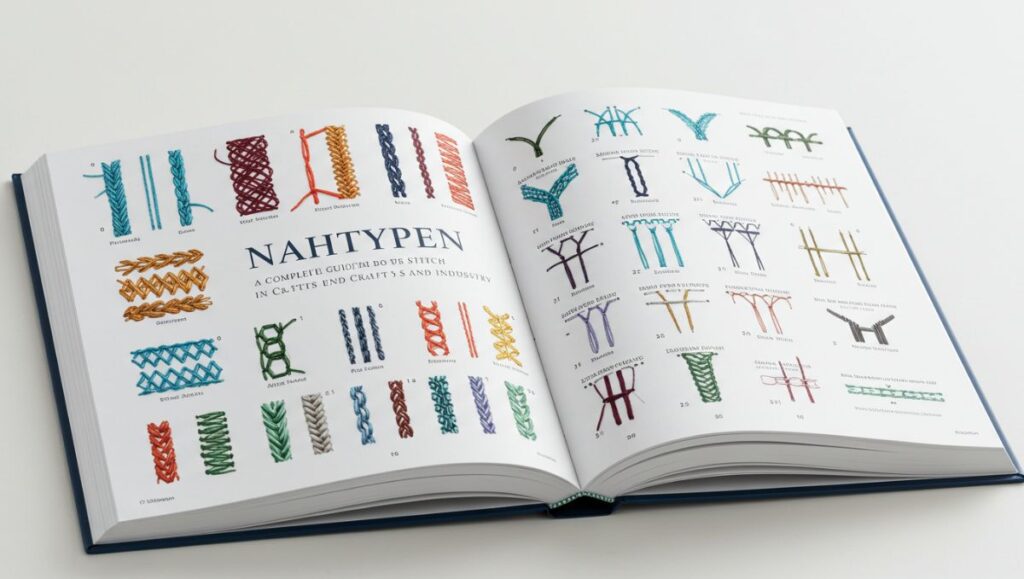

Basic Nahttypen Overview

There are many kinds of stitches, each designed for specific purposes. Below are the most common nahttypen:

1. Straight Stitch

The straight stitch is the most widely used type. It consists of a row of straight stitches and is perfect for light to medium fabrics. While versatile, it lacks elasticity.

2. Zigzag Stitch

The zigzag stitch is flexible and durable. It is often used for stretchable fabrics, as it allows the material to move without tearing. It also prevents fabric edges from fraying.

3. Chain Stitch

This decorative yet functional stitch is valued for its elasticity. It is common in embroidery and denim manufacturing, where both strength and design matter.

4. Overlock Stitch

An overlock stitch trims, sews, and finishes edges in one step. It is highly popular in the fashion and textile industry to achieve professional-looking seams.

5. Double Topstitch

Double topstitching creates strong, reinforced seams. It is widely used in clothing that requires high durability, such as jeans, jackets, and workwear.

6. Flatlock Stitch

Flatlock stitching lies flat against the skin, making it ideal for sportswear and activewear. It prevents irritation and provides comfort during movement.

Nahttypen by Application

In the Fashion Industry

In apparel, appearance is just as important as functionality. Decorative stitching adds visual appeal, while overlock seams create a neat and clean finish.

In Home Sewing and Crafts

Hobby sewers often use a variety of nahttypen for both practical and creative projects. From simple joining seams to artistic topstitching, stitch choice directly affects the outcome.

In Industrial Production

Industrial settings demand efficiency and strength. Automated machines use high-speed stitching methods designed for heavy workloads and consistent results.

In Metalwork and Welding

Not all stitches involve fabric. In metal construction, welding seams are crucial. Common nahttypen include butt welds, fillet welds, and circular welds, each suited to specific stress levels and material types.

Advantages and Disadvantages of Nahttypen

Advantages

-

Wide range for different fabrics and applications

-

Combination of strength and aesthetics possible

-

Improved seam quality extends product lifespan

Disadvantages

-

Wrong stitch choice can damage material

-

Some stitches require specialized machines

-

Complex stitch types increase production time

How to Choose the Right Nahttypen

When selecting a stitch type, consider:

-

Fabric – Stretchy fabrics need elastic stitches.

-

Purpose – Stress-prone areas need strong stitches.

-

Design – Decide whether the stitch should be visible or hidden.

-

Tools – Some stitches require advanced equipment or specific skill levels.

Care and Durability of Stitches

Even the strongest seams need maintenance. Regularly checking stitches prevents small issues from turning into bigger problems. For sportswear or frequently used garments, monitoring seam strength is especially important.

Future of Nahttypen

With digitalization and automation, new seam technologies are emerging. Laser cutting and thermal bonding are increasingly replacing traditional stitches in industries like fashion, medicine, and engineering. These innovations improve durability, reduce waste, and open up new design possibilities.

Conclusion

Nahttypen are a crucial element in both textile and metalwork projects. From simple straight stitches to advanced welding seams, the variety of techniques is vast. By understanding the strengths and applications of different stitch types, professionals and hobbyists alike can achieve long-lasting, durable, and visually appealing results.